Solenoid Directional Valves

Solenoid directional air valves utilize an electric solenoid coil to control position of the valve's main spool or plunger via a manual switch, PLC output, or relay contact. The control voltage can be any of many AC or DC voltages available. Solenoid valves may be direct solenoid or solenoid pilot operated.

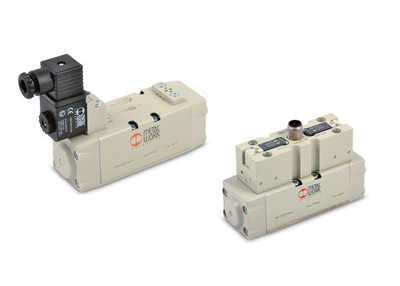

Direct solenoid variations normally allow for operation in low pressure or vacuum applications, and many designs allow for using the valve in normally closed, normally open, diverter, or mixing modes. Most direct-acting solenoid valves are available in 2-way or 3-way configurations.

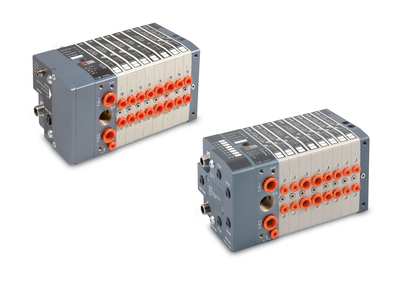

Solenoid pilot valves require a minimum operating pressure, but offer options not generally available in direct acting models, such as 2-position 4-way double solenoid, 3-position 4-way double solenoid, with or without center (blocked, exhaust, pressure center). This design also offers lower operating current and higher flow rates than direct acting models. Many solenoid pilot style air valves can control low pressure air with a simple dedicated external pilot supply. Note: The terms 4-way and 5-way are often used interchangeably, but the function is essentially the same. 4-way refers to a valve with (1) supply port, (2) working/outlet ports, and (1) common exhaust port. The 5-way version has an additional exhaust port, for a total of 5 ports. The 5-port variety is useful in cylinder applications where exhaust flow controls are used, as they can be set to control cylinder speed in each direction independently.