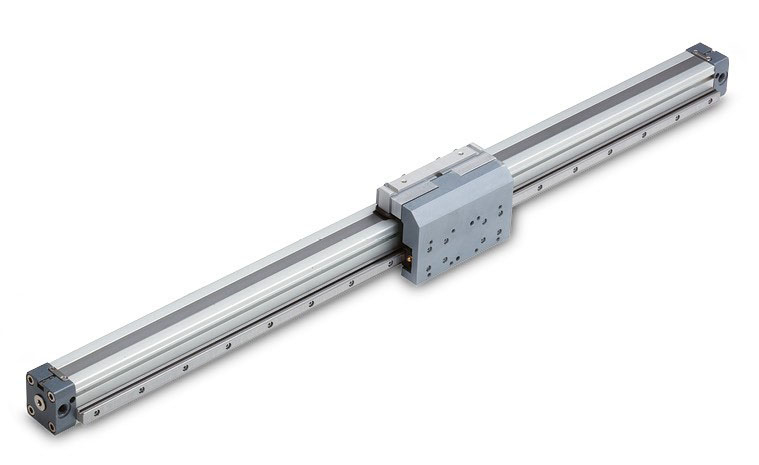

Metal Work Rodless Cylinder with Integral Ball Bearing Slide

The range of rodless cylinders with ball circulation guides is available with five different bores- 16, 25, 32, 40 and 63. The bore 63 can be supplied in two versions: the "standard" one for intermediate loads and the "heavy" one for considerably weighty loads.

> Metal Work Rodless with Recirculating Guide catalog pages

> Accessories/Parts catalog pages

Besides the general features specified for standard rodless cylinders, the other main features are:

- Very high load capacity, acting in all directions without discharging onto the cylinder slide.

- Hardened steel guide connected firmly to the cylinder barrel.

- Ball circulation pads constructed using special technology that make them very silent when the guide slides, with very long maintenance intervals. For example, they only need lubricating every 2000 km or once a year, using type 2 grease, preferably containing lithium soap.

- Extra sturdy slide support with various holes for fixing the loads. Holes for centering pins are also provided.

- 100 to 2650 stroke at intervals of 1 mm.

- Integrated pneumatic adjustable cushioning.

- Adjustable limit switches and decelerations can be applied at any time. For this type of cylinder (size 32 and upwards), the valves can be fitted directly using the retracting sensors without requiring any intermediate brackets.