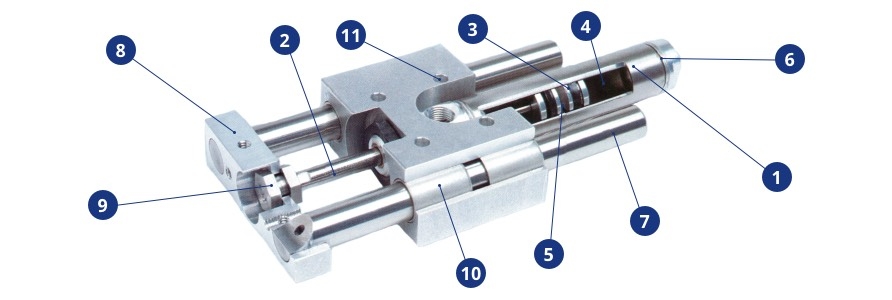

American® LSC Series Thruster Slides

|

|

> Download American LSC Series Catalog

1) Cylinder Body: Type 304 Stainless Steel tubing with strict specifications and tolerances to ensure longer cylinder life. 5/16" through 1-1/2" bore sizes.

2) Piston Rod Assembly: Ground & Polished Type 303 Stainless Steel piston rod with special accuracy specifications is threaded, anaerobically sealed and machine staked into the piston for triple protection.

3) Buna-N U-Cup Rod & Piston Seals: U-Cup seals provide low breakaway friction and extended seal life. Standard Buna-N seals recommended for temps between -20°F and 200°F. Fluoroelastomer seals are available for higher temperature applications. Additional special seal compounds and lubricants available upon request.

4) Prelubricated: All cylinders are factory lubricated with a special high endurance oil.

5) Magnetic Piston Band: All units (except 5/16" bore) provided with magnetic piston band for position sensing. Solid state and reed switches available separately.

6) End Caps: High strength aluminum alloy

7) Guide Shafts: Large diameter, special accuracy hard chrome plated 303 stainless steel guide shafts act as the inner race for the precision sleeve bearings, and provide a rigid attachment for the tool bar.

8) Tool Mounting Bar: Sturdy aluminum alloy with machined top and front surfaces with tapped mounting holes standard. Special configurations upon request.

9) Floating Rod Coupler: Prevents cylinder rod binding, ensuring smooth operation and long life.

10) Shaft Bearings: High performance Duralon sleeve bearings have a composite liner of low friction, self-lubricating fibers with filament-wound fiberglass reinforcement, with an epoxy shell to provide smooth motion and high load capabilities.

11) Mounting Holes: Standard thru-hole design for cap screw mounting. Optional threaded mounting holes (option "T").